Batch size under 50 boards?

Set-up time under one minute

No programming or deep expertise needed

Air-gapped solution

Compatible with secure, on-premise deployment

Customizable

Designed to adapt to your specific component library

It is really this easy

1. Upload Golden PCBA Photo

Upload an image of First Article Inspection Board as the golden reference

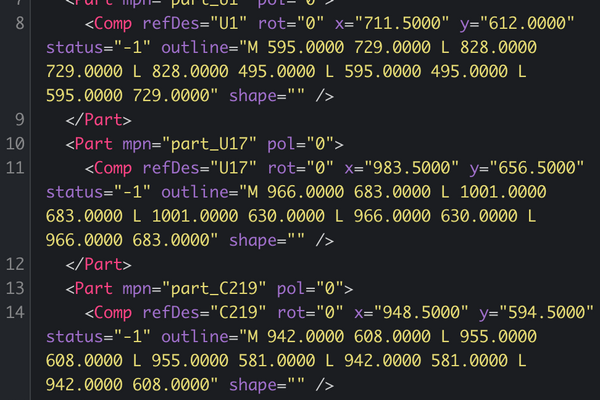

2. Upload Bill Of Materials

Add BOM file with the component coordinates. (All formats supported).

3. Start Inspecting Your Batch

Immediately see the difference with the golden board

Filter out defect-free parts – inspect only what matters

An affordable CAPEX solution for semi-automated visual inspection of electronic boards

AOI machines are expensive and come with a long setup time. Manual inspection is slow and unreliable process (and not so scalable). With Robovision we turn digital microscopes into automated inspection work stations at a fraction of the cost.

Cut your board inspection time by half

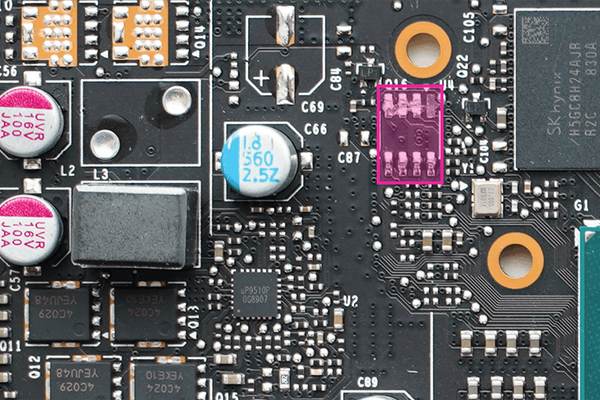

Missing components often stem from pick-and-place errors, reflow displacement, or post-reflow handling mistakes—but regardless of the root cause, the Robovision AI system reliably detects errors.

Wrong components usually result from feeder loading mistakes, pick-and-place program errors, or manual assembly mix-ups—no matter the root cause, the Robovision AI system spots them.

Polarity issues are sometimes caused by from feeder orientation errors, pick-and-place program mistakes, or manual placement oversights. Whichever the root cause, know that the Robovision AI system can find them.

Quality control that integrates across multiple locations of your production line

1. Income PCB Quality Control

Prevent downstream failures. Bare PCB defects often include open circuits, shorts, misregistration, solder mask issues, plating voids, and delamination. Regardless of the defect type, the Robovision AI system can reliably detect flaws before assembly.

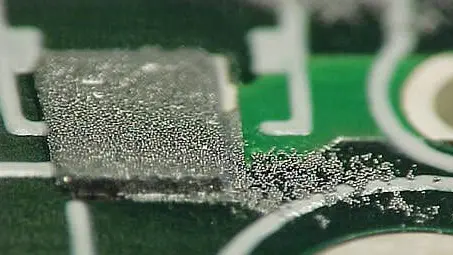

2. SPI Control

SPI (Solder Paste Inspection) defects often include insufficient paste, excess paste, misaligned deposits, bridging, and paste smearing. Regardless of the defect type, the Robovision AI system reliably detects paste issues to ensure stable and repeatable soldering quality.

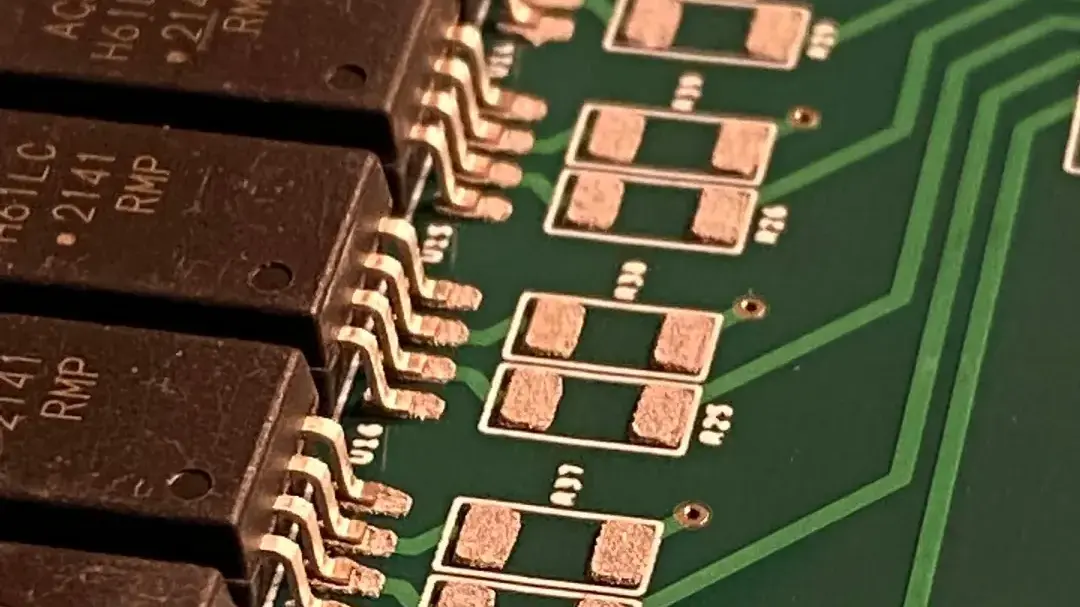

3. Pre-reflow Inspection

Pre-reflow inspection defects can include missing components, misaligned placements, wrong components, and polarity errors. Detecting them at this stage is critical to prevent defective boards from being soldered, which drastically reduces rework costs, minimizes scrap, and preserves high production yield. The Robovision AI system can reliably catch them early to insure product quality regardless of the defect type.

4. Post-reflow Inspection

Post-reflow inspection reveals defects that only occur during the soldering process, such as cold solder joints, solder bridges, voids in solder joints, and component movement during reflow (tombstoning, skewing, or lift-off). While many soldering-related issues require X-ray or electrical testing, the Robovision AI system is specifically designed to detect missing components, rotated components, and significant component movement—defects that cannot be reliably identified before this stage.

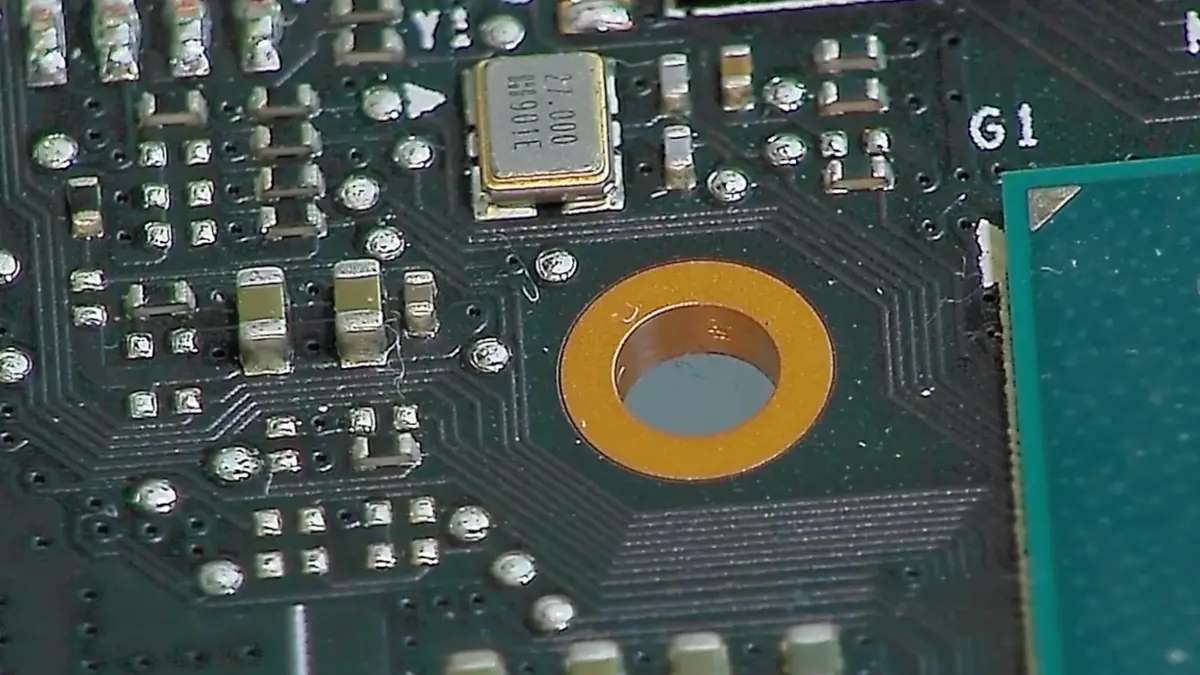

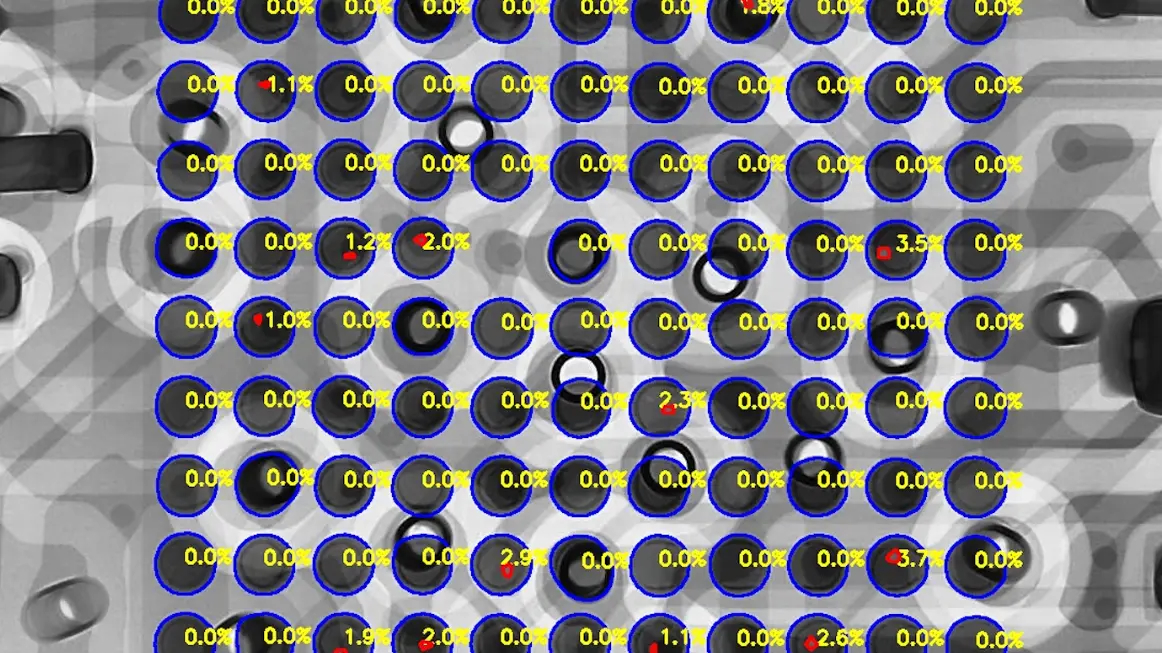

5. X-ray Inspection

X-ray electronics inspection is essential for identifying hidden defects in components like BGAs, where solder joints are not visible. One of the most critical issues it detects is voiding inside solder balls, which can weaken mechanical strength, reduce thermal dissipation, and lead to electrical reliability failures. The Robovision AI system analyzes X-ray images to accurately detect and quantify solder voids in BGAs, helping ensure assemblies meet IPC Class 2 or Class 3 requirements.

Find out how automation can change your business

Success Stories

Vision AI-based defect detection for high-speed laminate manufacturing.

View success story

Robovision's AI Helps Eurocircuits Simplify and Perfect PCB Visual Inspection

View success story