AI-Powered Vision for Reliable and Scalable Wood Quality Inspection

The Challenge of Detecting Defects in Natural Wood Materials

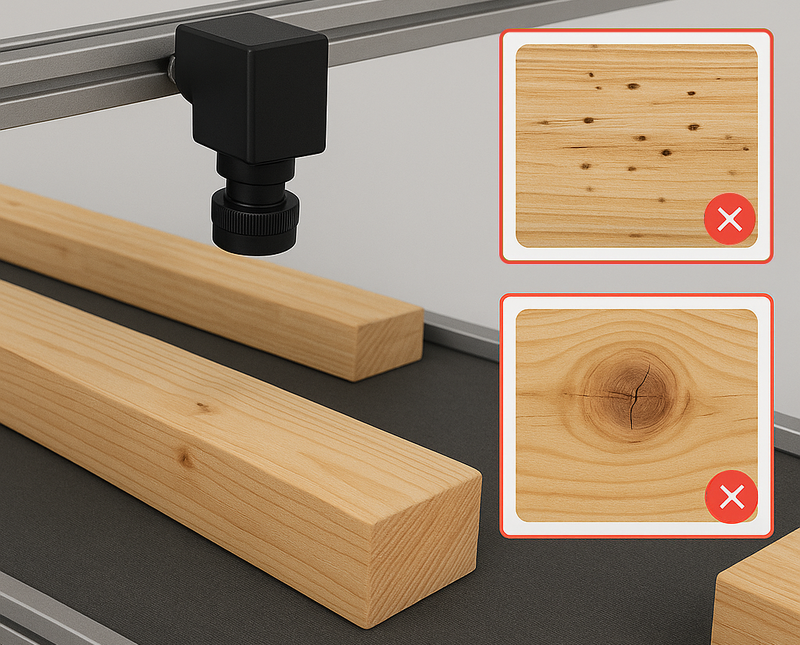

Wood is a complex, variable, and living material—no two boards are alike. That variability makes inspection difficult. Defects such as knots, cracks, wormholes, discoloration, resin pockets, or warping can affect usability, strength, and visual grade. Manually identifying and classifying these issues is labor-intensive, subjective, and hard to scale—especially in sawmills, furniture manufacturing, and flooring production.

Traditional rule-based systems often fail when faced with the natural variation in grain patterns, textures, or lighting conditions. What manufacturers need is a solution that understands the nature of wood—and learns to recognize defects across formats, species, and end-use standards.

How Robovision Automates Wood Defect Detection

With Robovision’s AI-powered Wood Defect Detection System, you can bring consistency, accuracy, and intelligence to your wood inspection process. Built on our AI Automated Defect Classification engine, our solution identifies and classifies a wide range of natural and process-induced wood defects, at industrial speeds.

What you gain with Robovision:

Multi-defect detection

Automatically identify knots (open or closed), splits, rot, resin pockets, stains, wormholes, rough surfaces, warping, and edge or surface damage.

Intelligent classification

Each defect is labeled and categorized according to your grading standards (e.g., furniture-grade vs. construction-grade), enabling automation of downstream decisions.

Species and format versatility

Adapt easily to hardwood, softwood, plywood, veneer, or laminate—regardless of color, grain, or finish.

In-house model adaptability

Operators can quickly train or fine-tune AI models via a no-code interface, responding to seasonal or supplier-driven variations without reprogramming.

Robovision helps turn a subjective, manual task into a scalable digital process—reducing waste, improving yield, and boosting the value of every board you produce.

Nature’s Material, Inspected with Artificial Intelligence

Robovision brings speed, accuracy, and intelligence to wood inspection—letting you meet production goals without compromising quality.

Smarter grading. Better yield. Fewer surprises.

Let’s bring AI vision to your wood production line