AI-Powered Vision for High-Precision Inspection of Composite Materials

The Challenge of Inspecting Carbon Fiber Components

Carbon fiber is prized for its strength-to-weight ratio, but inspecting it for defects is one of the most challenging tasks in advanced manufacturing. Defects such as fiber misalignment, delamination, voids, wrinkles, foreign material inclusion, and surface anomalies can compromise the structural integrity of high-performance components used in aerospace, automotive, defense, and sporting goods.

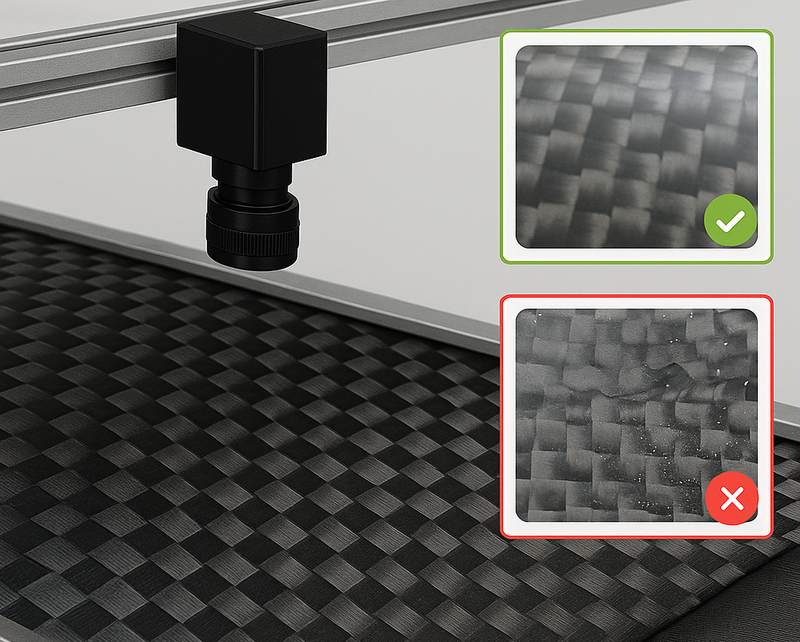

Traditional visual inspection methods are slow, subjective, and often miss subtle but critical flaws—especially in complex part geometries or woven structures. Automated systems based on fixed rules struggle to adapt to variations in texture, lighting, and production tolerances. A smarter, learning-based solution is essential.

How Robovision Brings Intelligence to Carbon Fiber Inspection

Robovision’s AI-powered Carbon Fiber Defect Detection System is designed to tackle the complexity and precision demands of composite materials. Built on our AI Automated Defect Classification engine, our solution identifies, classifies, and localizes multiple defect types in real time—while learning and improving over time.

Our platform delivers:

Multi-class defect detection

Identify a full range of carbon fiber issues, including fiber misalignment, wrinkles, resin-rich/poor zones, voids, foreign object debris (FOD), and delamination indicators.

High-resolution classification

Defects are not only detected, but also categorized by type, location, and severity—providing traceability for process control and root-cause analysis.

Adaptable across formats

Whether you’re inspecting raw sheets, pre-pregs, molded parts, or cured components, Robovision adapts to your geometry, material finish, and inspection method.

AI model control in your hands

Use our no-code interface to train, validate, and deploy new models as materials, production parameters, or part designs change.

With Robovision, you unlock consistent, reliable carbon fiber inspection without compromising throughput or operator bandwidth—ensuring your lightweight components meet the most demanding performance standards.

Precision Inspection for High-Performance Materials

Robovision brings intelligent defect detection to carbon fiber manufacturing—reducing waste, improving quality yields, and enabling data-driven process improvements.

Elevate your composites with smarter vision.

Let’s inspect carbon fiber the way it deserves—using AI.