AI-Powered Plastic Sorting for Smarter, Cleaner Recycling

The Challenge of High-Precision Plastic Waste Sorting

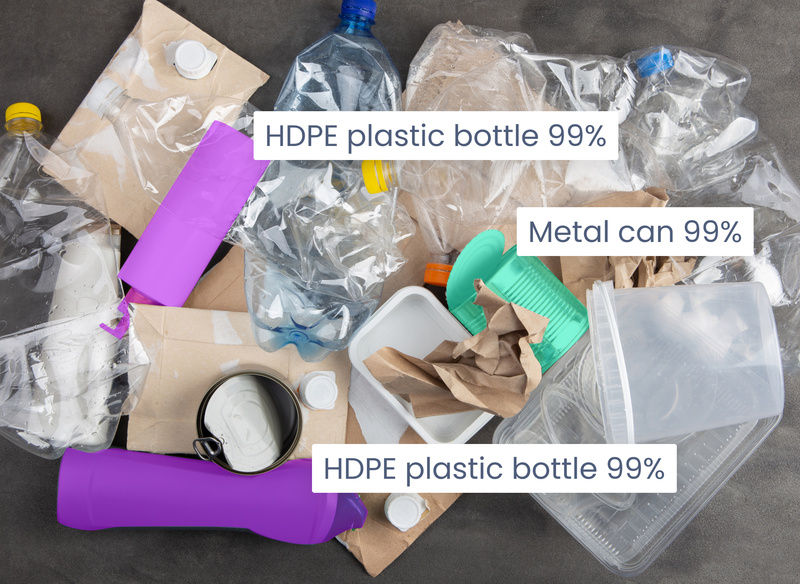

Efficient recycling starts with accurate sorting—but separating plastics by type, color, or contamination level is still largely reliant on outdated mechanical systems or manual labor.

These traditional methods struggle to identify multi-material items, detect contaminants, or adapt to ever-evolving packaging materials. The result? Lower-quality recyclates and high operational costs. As regulations tighten and sustainability targets grow, recyclers need a scalable, intelligent solution that keeps pace.

How Robovision Makes Plastic Sorting Smarter

Robovision's computer vision platform transforms plastic sorting with real-time, high-accuracy detection powered by deep learning and 2D imaging. Our Optical Sorting Plastics solution builds on our proven 2D Grading & Picking technology, tailored to the unique needs of the recycling industry.

Key capabilities include:

Material recognition

Sort plastics like PET, HDPE, PP, and more by visual features.

Color-based separation

Accurately differentiate between clear, colored, and opaque plastics.

Contamination detection

Identify labels, food residue, or other non-plastic elements.

Model adaptability

Train your system to recognize new packaging or local waste streams.

With Robovision, teams can train, fine-tune, and deploy AI models quickly—no coding needed. This makes it easy to adapt your sorting logic as material streams shift or recycling standards evolve.

A New Era for Plastic Recycling

Our Optical Sorting Plastics solution helps recyclers boost purity rates, reduce manual effort, and increase the value of recovered materials. Whether you’re a local facility or part of a global recycling network, Robovision brings the intelligence and flexibility you need to meet tomorrow’s sustainability goals—today.

Ready to recycle with vision?

Let’s sort smarter, together.