AI-Powered Tomato Sorting for Perfect Color, Ripeness, and Quality—Every Time

The Challenge of Sorting Tomatoes at Scale

Tomatoes are delicate, highly perishable, and visually diverse—making consistent sorting a serious challenge. Manual inspection for ripeness, size, bruising, and skin defects is labor-intensive and often inconsistent, especially at industrial speeds.

Whether for fresh market, processing, or packaging, producers need a fast, reliable solution to meet quality standards and minimize waste.

How Robovision Makes Tomato Sorting Smarter

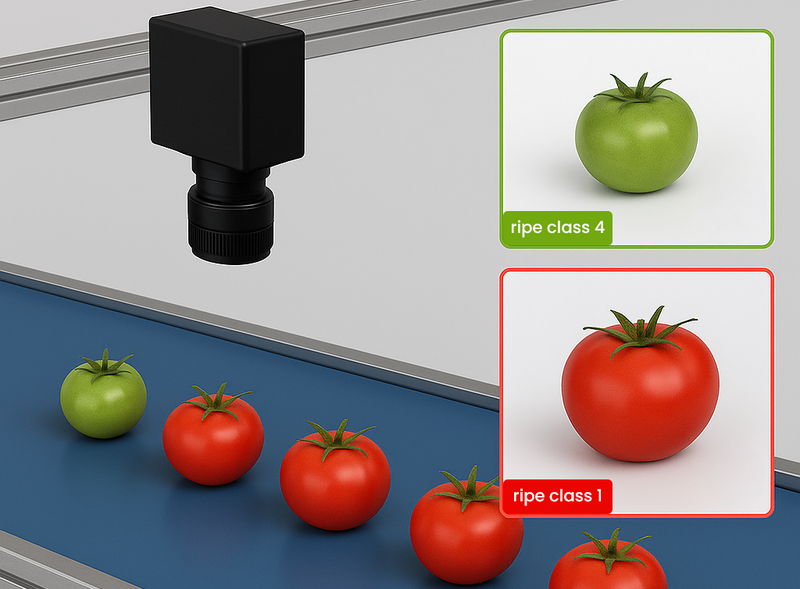

Robovision’s Tomato Optical Sorter combines advanced computer vision and deep learning to deliver accurate, real-time grading using 2D image data. Built on the same foundation as our proven 2D Grading & Picking platform, this solution empowers packhouses and processors to automate sorting without sacrificing precision.

Key features include:

Ripeness & color detection

Sort by maturity stage with precision.

Size and weight estimation

Identify bruises, blemishes, cracks, and overripe spots.

Size and shape grading

Fast, non-contact measurement.

Easy integration

Fits seamlessly into existing conveyor and packing systems.

The Robovision AI Platform enables non-technical users to train, deploy, and update AI models quickly. Rather than being completely dependent on a data science team, factory domain experts can easily adapt the grading rules to meet evolving quality standards or seasonal changes in crop appearance.

A Fresh Standard in Tomato Processing

Robovision’s Tomato Optical Sorter brings consistency, speed, and intelligence to your production line. Whether you're sorting cherry, plum, or beefsteak tomatoes, our AI ensures you deliver the highest quality product with maximum efficiency.

Ready to sort smarter?

Let’s bring vision to your tomato line.