AI-Powered Inspection for Precision Metal Quality Control

The Challenge of Reliable Metal Defect Detection in Modern Industry

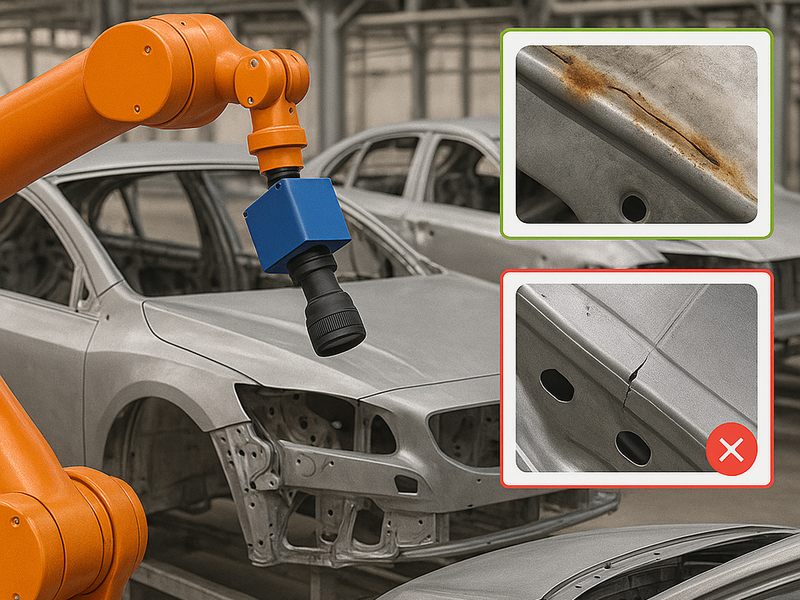

In industries like automotive, aerospace, electronics, and metal fabrication, the structural integrity of metal components is non-negotiable. Yet, detecting subtle surface and structural defects—such as scratches, dents, cracks, corrosion, discoloration, or burrs—is difficult to scale with human inspection or rigid rule-based systems.

High-speed production lines, reflective surfaces, and a wide range of part geometries only complicate the challenge. Traditional systems often miss nuanced defects or generate false positives—slowing production and eroding confidence. What’s needed is a vision system that can not only detect defects, but also understand and classify them with precision.

How Robovision Transforms Metal Inspection

Robovision’s AI-driven Metal Defect Detection System empowers manufacturers with advanced visual intelligence—capable of identifying, classifying, and tracking multiple types of metal defects in real time. Built on our AI Automated Defect Classification platform, the system evolves with your production needs, helping you catch more, waste less, and act faster.

Robovision delivers:

Multi-defect detection

Accurately spot and differentiate between scratches, pits, cracks, corrosion, surface inconsistencies, burrs, and discoloration—even in varying lighting and reflection conditions.

Intelligent defect classification

Automatically categorize defects by type, severity, and location for traceability, process optimization, and quality reporting.

Adaptable to complex parts

Inspect flat sheets, coils, castings, machined parts, and stamped components—even with irregular shapes and finishes.

Operator-friendly model management

Enable quality teams and engineers to update and adapt models without code, accelerating response to new defect types or part designs.

With Robovision, manufacturers gain full visibility into quality performance—reducing costly rework, improving downstream assembly yields, and ensuring compliance with even the strictest industry standards.

Metal, Perfected by Machine Vision

Robovision turns metal inspection into a strategic, AI-enabled quality process—capable of scaling with your line, your parts, and your standards.

Let’s inspect smarter.

Put AI vision to work on your metal components.