AI-Enhanced Vision for Complete Bottle Quality Assurance

The Challenge of Comprehensive Bottle Inspection at Scale

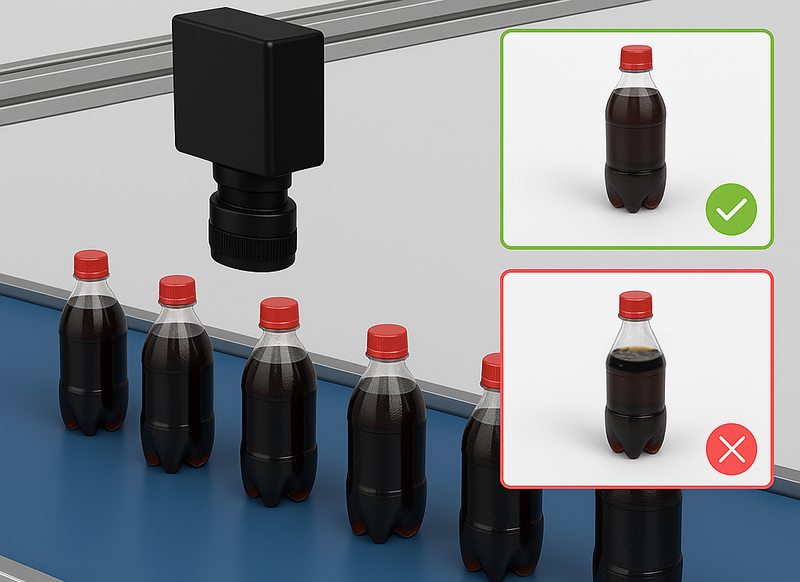

In high-throughput production environments—especially in food, beverage, cosmetics, and pharmaceutical sectors—bottle defects can compromise safety, regulatory compliance, and brand reputation. From cap misplacement to fill level variation, label misalignment, or structural cracks, even small issues can have significant downstream costs.

Manual inspection and traditional systems fall short in keeping pace with production speeds or detecting the full range of potential defects across diverse bottle types, materials, and configurations. Manufacturers need a smarter solution—one that not only detects issues, but understands them.

How Robovision Optimizes Bottle Inspection

Robovision’s AI-powered Bottle Inspection System uses state-of-the-art computer vision and our robust AI Automated Defect Classification engine to inspect every bottle with precision—detecting, classifying, and tracking multiple defect types in real time.

Our platform provides:

Multi-defect detection capabilities

Identify issues such as cap misalignment or absence, incorrect or missing labels, fill level inconsistencies, barcode or date code defects, and much more.

Automated defect classification

Every detected flaw is labeled and categorized to drive analytics, reporting, and quality improvement.

Versatile bottle handling

Adaptable to inspect glass, PET, HDPE, and custom-shaped containers across various production lines.

Smart model management

Your operators can train, adjust, and deploy AI models easily via our no-code interface, adapting inspection logic to new products or formats instantly.

Robovision makes it easy to transform your inspection workflow from reactive to proactive—enabling continuous improvement and scalable compliance.

Vision That Sees Every Flaw, and Learns from It

From production line to shelf, Robovision ensures every bottle meets your highest quality standards. Reduce waste, minimize downtime, and maintain consumer trust with intelligent, automated inspection..

Every bottle. Every detail. Perfected.

Let’s deploy AI vision on your bottling line.