Robovision 5.9: The AI Model Monitoring Tool for Industry

Date Section News

AI is transforming manufacturing landscapes globally, but it is crucial to recognize the evolutionary nature of this shift. Deploying AI models is not a “set and forget” process. In dynamic production environments, models naturally degrade over time, leading to inefficiencies and errors.

Robovision’s 5.9 release introduces Inference Monitoring; an AI model monitoring tool that tracks vision AI model performance and identifies when intervention is needed. By detecting shifts in data and model behavior, The Robovision AI Platform provides the insights necessary to determine when further AI training is required, helping maintain reliability and transparency throughout deployment and operation.

How It Works: Model Performance Tracking and Drift Detection

When new materials or products are introduced on a production line, for example, the AI model monitoring software identifies changes that may lower prediction confidence. It then automatically suggests model retraining to maintain performance.

AI inference monitoring can be configured to analyze multiple key metrics like:

- Unknown rate: Identifies instances where the model encounters unfamiliar data.

- Amount of predictions: Tracks sudden spikes in prediction volume.

- Predictions per class: Monitors class distribution, detecting disproportionate or imbalanced predictions.

When performance deviates from predefined thresholds, the system flags potential issues, allowing operators to intervene promptly. This proactive approach aids in the prevention of unplanned downtime and quality defects resulting from data drift.

Continuous Monitoring Equals Long-Term Value

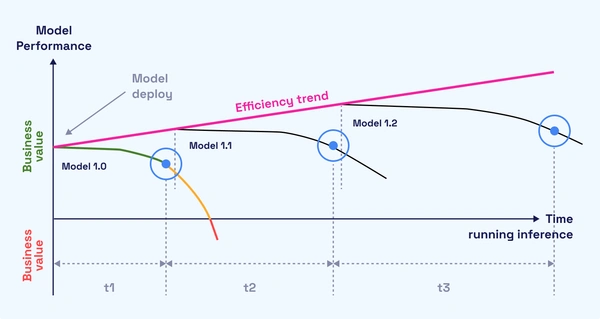

Frequent model upgrades informed by Inference Monitoring thresholds do not simply maintain AI model performance, they enhance and improve it. As the system flags interventions, each retraining cycle fine-tunes the model to evolving production conditions.

The importance of robust AI model monitoring tools cannot be overstated—continuous model improvement drives greater precision and adaptability on a continuous scale. The long-term value is massive in dynamic production environments.

AI Model Monitoring: Why Inference Monitoring Matters

Why is continuous monitoring important in AI model management? Without real-time visibility into model behavior, identifying the root cause of performance degradation is challenging, potentially leading to costly downtime and compromised product quality. Inference Monitoring is like a “health check” system for model performance.

Manufacturing environments are complex and unpredictable. Variability in input data—such as shifts in lighting, dust build-up on lenses, or changes in conveyor speeds—affects model performance. This data drift gradually degrades model accuracy and reliability.

Scaling AI solutions across multiple production lines presents additional challenges, requiring flexible, robust monitoring systems. Robovision 5.9’s introduction of Inference Monitoring observes AI outputs, and flags issues before they escalate, improving:

- Quality Control – Real-time AI model monitoring detects inconsistencies early on, reducing waste and ensuring only high-quality products reach customers.

- Operational Efficiency – Optimizes production speeds and throughput by maintaining inference accuracy without slowing down the line.

- Error Diagnosis and Traceability – Quickly pinpoint deviations in AI performance, whether due to model drift, input variations, or system anomalies, enabling swift interventions and informed reporting.

Cost Reduction – Early issue detection minimizes downtime, reducing manual inspection costs and waste. For example, detecting early signs of wear—like a sweating rubber seal—allows intervention before a failure impacts production.

Lifting the Veil: Trusting AI to Optimize Operations

Model monitoring in AI gives greater visibility into model performance, helping track accuracy and detect issues before they affect production. By offering real-time insights, Inference Monitoring provides a deeper level of control over AI-driven processes.

Transparency into AI performance is key to building trust in a technology that is rapidly becoming an essential part of modern manufacturing. Robovision’s Inference Monitoring is more than just a safeguard—it not only ensures AI systems continuously adapt and improve but, in a larger sense, empowers manufacturers to take a leap forward in an era where agility and technological adaptability define the future of industry.