Pixel-Precise Paint Defect Detection with Vision AI

In manufacturing, manual paint inspection puts quality and reputation at risk. Paint defects often slip past slow, error-prone human inspection and traditional vision systems lack the adaptability to keep up.

So when production scales and quality standards tighten, manual checks fall short—jeopardizing both customer satisfaction and brand reputation. The financial impact that follows is painful: post-production fixes up to 10 times more costly than inline detection. These risks make pixel-level precision and early defect detection non-negotiable.

Robovision’s Vision AI Platform transforms paint inspection with accurate, automated defect detection for every stage of the process. Scalable integration, adaptive learning, and predictive insights translate to faster detection. For manufacturers, the result is less rework and better first-time quality, with no need for extra overheads.

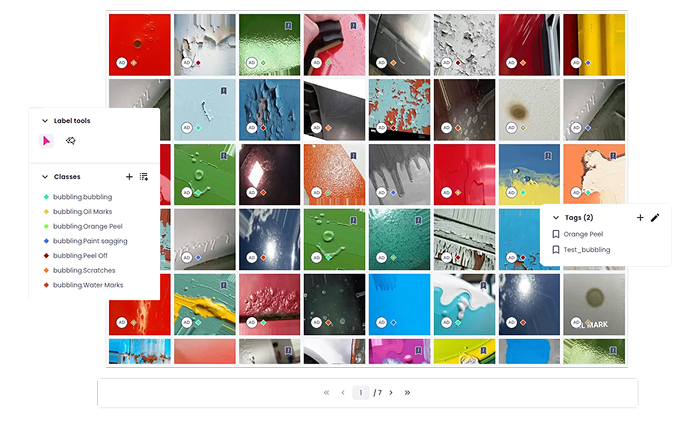

How Robovision Enables Precise and Continuous Paint Defect Detection

Pixel-Level Accuracy

Eliminates variation due to human fatigue or bias. In real time, detects micro-defects below the human perception threshold during production. Enables corrective action with surface inspection of paint quality and early detection of fisheyes, dirt nibs, or orange peel texture. Monitors multi-phase paint processes, identifying potential defects faster.

Adaptive Learning

Trains across different surface types, colours, lighting, and defect categories. Consistently improves accuracy by learning from new data and patterns. By deploying their own AI deep-learning models, manufacturers can improve bodywork paint standards and optimize inspection accuracy, without increasing scarce labour overhead.

Scalable Integration

Integrates with existing manufacturing systems. Augments automated inspection systems by providing an added layer of security. For example, if a rules-based system rejects a part, the Robovision AI Platform can reevaluate the part to distinguish between an actual defect and an acceptable variation, reducing false positives.

High-Speed Processing

Logs defect type, frequency, and location for traceability and process improvement. Analyzes vast amounts of visual data quickly, maximizing production uptime. Enhances and increases accuracy, precision, efficiency, and inspection capacity in paint defect detection, supporting real-time inspection at speeds human inspectors can’t match.

What Robovision Can Do: Industry Applications

Reduce Costly Repaints

Problem: Defects like edge fade, runs, and sags lead to costly repaint jobs.

Vision AI Solution: Automated defect inspection across surface types.

Impact: $millions saved in potential repaint work / Up to 10 times reduction in paint repair costs

Ensure Full Coverage

Problem: Inconsistent edge paint where panels meet trim, glass, or rubber.

Vision AI Solution: Inspects all areas with pixel-point accuracy.

Impact: Ensures uniform coating and reduces long-term quality risks

Deliver Premium Finish at Scale

Problem: Downstream issues lead to brand damage and lost revenue.

Vision AI Solution: Matte, gloss, and metallic finishes inspected at unmatched speeds.

Impact: Up to 10 times reduction in paint repair costs

Improve Finish Standards/Increase Customer Confidence

Problem: Paint defects diminish perceived value.

Vision AI Solution: Consistent, scalable inspection standards that ensure aesthetic appeal.

Impact: Boosts customer trust and brand reputation.

Meet Cleanroom Standards

Problem: Surface defects compromise performance and release particulates.

Vision AI Solution: Automates inspection under cleanroom-compatible conditions.

Impact: Paint that ensures anti-corrosion, static protection, and cleanliness.

Solve Multi-Phase Complexity

Problem: Defects occur at any stage of a multi-phase paint operation.

Vision AI Solution: Automates defect detection across all stages, from priming to drying.

Impact: Enhances durability and aesthetic appeal / Up to 10 times reduction in paint repair costs.