AI-Driven, Multi-Defect Packaging Quality Control at Industrial Scale

The Challenge of Detecting Diverse Packaging Defects at High Speed

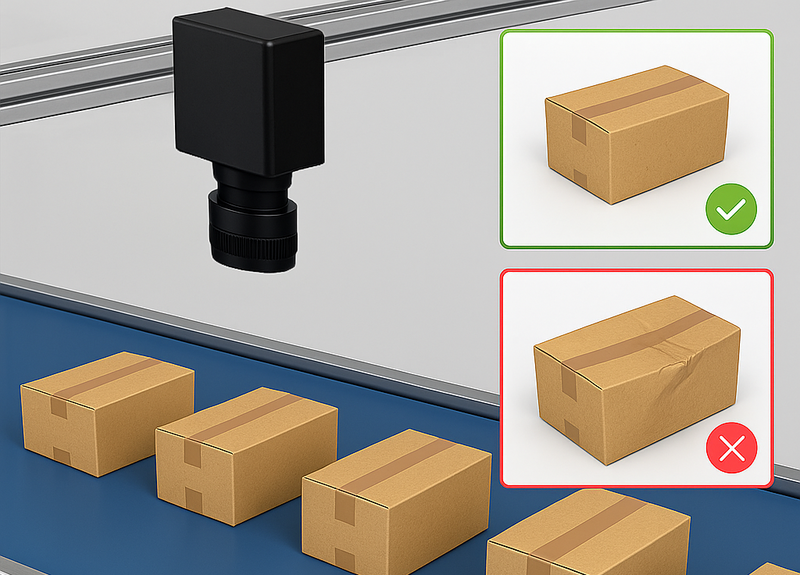

Modern production environments demand flawless packaging—seals must be tight, labels accurate, barcodes scannable, and surfaces free from contamination or damage. But detecting all possible defects across various packaging types, shapes, and formats is far beyond what manual inspection or rule-based systems can handle.

Manual checks are inconsistent, prone to fatigue, and limited in scope. Traditional automation often fails to capture subtle, multi-class defects. As expectations around traceability and quality grow, manufacturers need a more intelligent, scalable approach to ensure defect-free packaging at speed.

How Robovision Transforms Packaging Inspection

At Robovision, we bring powerful, AI-based vision capabilities to packaging lines—backed by our AI Automated Defect Classification technology. Our platform doesn’t just detect flaws; it intelligently identifies, classifies, and tracks multiple defect types, all in real time.

With Robovision, you gain:

Multi-class defect detection

Accurately detect and differentiate between seal faults, label misalignment, smudges, barcode errors, print issues, dents, tears, and contamination.

Defect classification and traceability

Go beyond detection: each defect is automatically labeled, logged, and categorized for root-cause analysis, process optimization, and compliance reporting.

Adaptable AI models

Continuously improve and refine models on your own terms—your line operators and QA teams can train and adjust inspection criteria via our no-code interface.

Real-time feedback loop

Our system provides immediate defect alerts, enabling corrective action before issues compound.

Built on a modular, easy-to-integrate platform, Robovision empowers teams to shift from reactive to proactive quality control—boosting productivity, reducing waste, and ensuring consistent packaging excellence.

Packaging Integrity at Scale

Robovision elevates packaging inspection from a basic pass/fail task to a strategic, data-rich process. Identify every flaw, understand every failure mode, and continuously improve your quality operations.

Let’s make every package perfect.

Discover how AI-powered vision can redefine your packaging quality.