Inspection Beyond Rules: Accelerate Your Yield Ramp at Semicon Europa

Starts Ends Location MESSE MÜNCHEN | München, Germany

Europe’s leading fabs are moving beyond rigid, rule-based inspection. Discover how Robovision’s Vision AI platform empowers your engineers to accelerate yield and move beyond static rules.

The Limits of a Rules-Based World

In semiconductor manufacturing, quality is the primary lever for yield, cost, and time-to-market. However, traditional rule-based inspection systems are holding you back. They are rigid by design and struggle with the slightest variability in defects. Every new defect type or process node requires months of complex rule engineering, delaying root cause analysis and slowing the introduction of new products.

The Solution: An Expert-in-the-Loop AI Platform

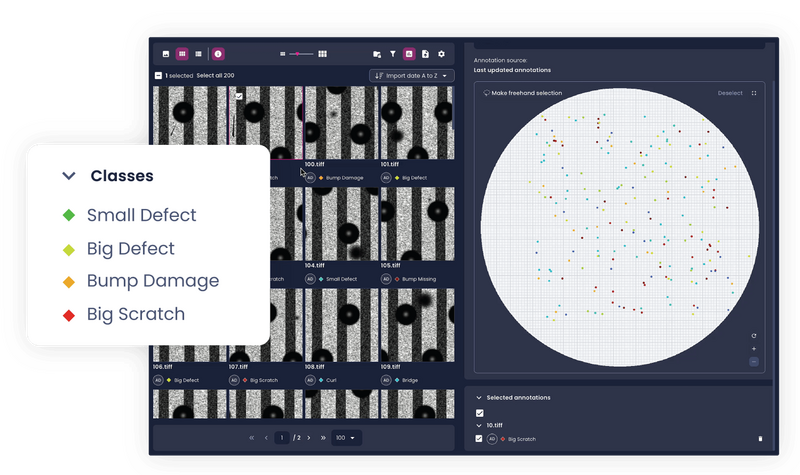

To accelerate yield, you need to go beyond rules. The Robovision platform enables a new approach by putting your own domain experts directly in the AI loop. Our low-code environment allows your engineers to train, validate, and continuously refine AI models, transforming Vision AI from a black box into a trusted co-pilot for yield improvement.

- Achieve Superior Accuracy: Reach detection rates of up to 99%, compared to ~85% for traditional rule-based methods.

- Empower Your Experts: Enable your process engineers to continuously refine AI performance, ensuring accuracy, trust, and faster adoption.

- Accelerate Yield Ramp: Join industry leaders who report 10-15% faster yield ramp-up on new nodes by leveraging advanced AI.

See 'Inspection Beyond Rules' in Munich

Visit us at booth C1206 in Hall C1 for a live demonstration of our adaptive AI platform. See for yourself how to move beyond static rules and turn quality into your sustained competitive advantage.

Build Your Roadmap to a Faster Yield Ramp

Generic demos don't solve specific problems. Book a private consultation with our Vision AI specialists at Semicon Europa to map out how an adaptive, expert-in-the-loop approach can solve your unique inspection challenges.